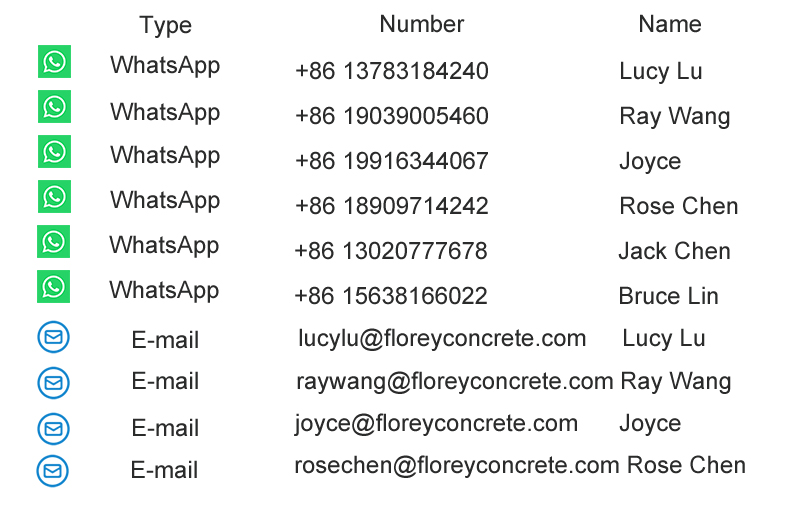

Polycarboxylate Superplasticizer Synthesis Process Equipment

Polycarboxylate Superplasticizer Synthesis

Product Description

If you are currently using polycarboxylate superplasticizers or are interested in the concrete admixture industry—and considering producing polycarboxylate yourself—we can provide you with a complete production solution, including equipment and manufacturing technology.

Polycarboxylate water-reducing agent synthesis factory construction concept: It takes one day to build the plant, and can produce product since the second day.

Fully Automated Multi-Function Polycarboxylate Superplasticizer Mother Liquor Synthesis Equipment

Equipment and factory construction: Quickly build factory with professional integrated modules. As soon as finishing simple operations including water and electricity connection and pipeline connection, you can produce qualified products .

Equipment advantages: small footprint, low-height feeding,low-height dripping.

Seven Major Systems:

- PLC Programmable Control System

- Automatic Small Material Dosing System

- Automatic Temperature Control System

- Automatic Weighing & Metering System

- Automatic Reaction & Mixing System

- Electrical Safety Control System

- Automatic Feeding & Discharging System

Key Advantages:

- Fully automated control – One-button operation, simple, convenient, and efficient.

- Single-operator efficiency – Reduces labor costs while improving measurement accuracy.

- Stable & mature process – Energy-efficient, eco-friendly, and cost-effective production.

- Compact & portable design – Integrated platform for easy installation and minimal floor space. Relocation requires only a forklift.

Our Services:

- Advanced formulation technology – Includes expert technical support for trials.

- Comprehensive solutions – We supply mother liquor production equipment, lab testing devices, technical formulations, raw materials, and on-site technicians (*optional, non-mandatory*).

- Professional team support – Saves you time, money, and effort, eliminating all post-installation concerns.

Technology Service

PCE production synthesis technology, concrete technology, concrete admixture technology

Welcome consultation: