Polycarboxylate Monomer HPEG/SPEG

Methyl allyl alcohol polyoxyethylene ether HPEG/SPEG

Download product file

Download product file

Product Description

HPEG/SPEG/C4 Monomer is the main raw material for the production of polycarboxylic acid superplasticizer, which is prepared by the reaction of methyl allyl alcohol and ethylene oxide. In the production process of PCE, it is generally used to produce water-reducing type water reducer, and the effect of it is not as good as that of TPEG/VPEG/IPEG. Polycarboxylate superplasticizer can be produced by free radical polymerization by heating method or oxidation - reduction method at room temperature.

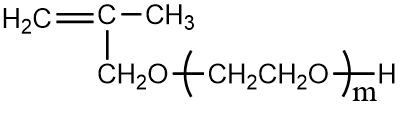

Product molecular structure

Molecular structure:

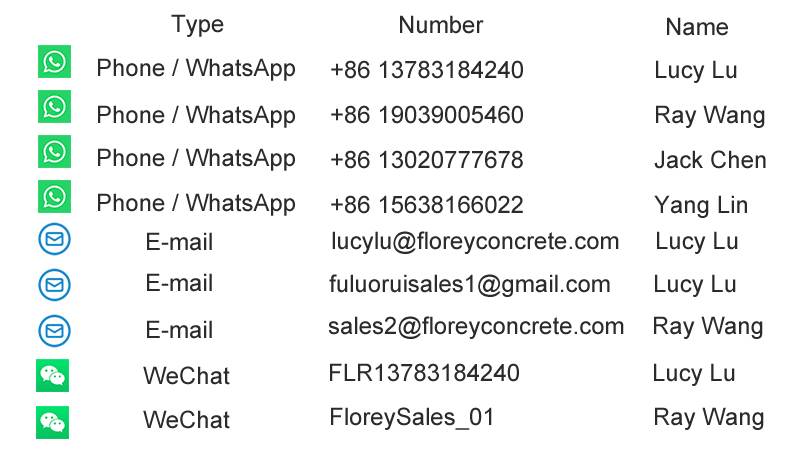

Technology Service

If you need to use HPEG to produce PCE water reducer, please contact our company, our company can provide a full set of production technology and process formula.

PCE production synthesis technology, concrete technology, concrete admixture technology.

Application

Polycarboxylic superplasticists produced by HPEG can be used to prepare many types of concrete, including but not limited to retarded concrete, precast concrete, cast-in-place concrete, high-performance concrete, flow concrete, self-compacting concrete and mass concrete. These concrete products can be widely used in high-speed railways, large Bridges, water conservancy, hydropower, nuclear power, subways, expressways, port terminals and various civil and industrial construction projects.