In recent years, the synthesis technology of polycarboxylate mother liquor has become increasingly mature through several updates and iterations, progressing from high-temperature esterification with pure water to the current tap water at room temperature method. This has significantly lowered the synthesis threshold for polycarboxylate superplasticizers. The raw materials for compounding polycarboxylate superplasticizers can be roughly divided into the following categories: polycarboxylate mother liquor, retarders, defoamers/air-entraining agents, water-retaining agents, anti-freezing agents, and early strength agents. This article focuses on introducing commonly used and conveniently adaptable types.

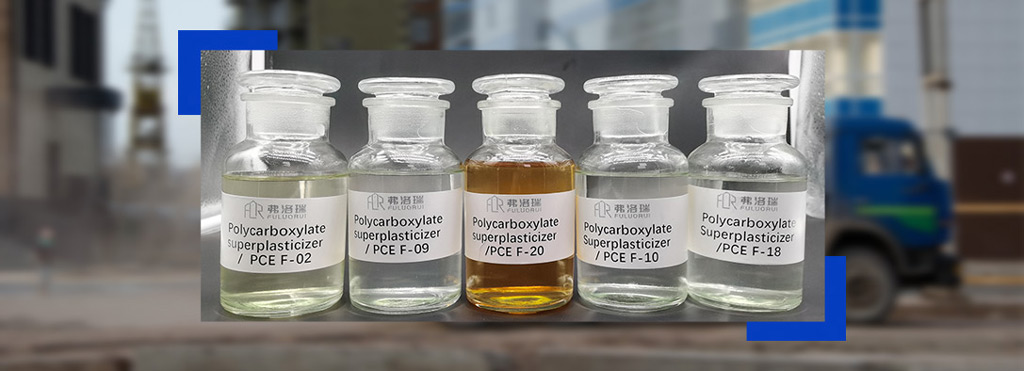

polycarboxylate superplasticizers Mother Liquor:

The most commonly used in a wide range of mother liquors are the water-reducing type and slump-retaining type.

By adjusting the ratio of acrylic acid to monomers, the water-reducing efficiency can be increased in polycarboxylate mother liquor, but it may sacrifice the slump-retaining performance of the mother liquor.

Retarders:

Sodium gluconate: It is inexpensive and provides a certain water-reducing effect. It offers the best cost-effectiveness and is the most common retarder in compounding. The disadvantage is that it may reduce the workability of concrete to some extent.

Sucrose: It is slightly more expensive but has a significant retarding effect and can improve the workability of concrete. The downside is that it increases the final setting time of concrete at low temperatures.

Maltodextrin: It is comparable in price to sodium gluconate and can improve the water-retaining performance of concrete. The drawback is that it may increase the slump loss of concrete.

Defoamers/Air-entraining Agents:

A certain amount of air-entraining agent in concrete is beneficial for improving its flowability, workability, and pumpability, reducing segregation and bleeding, and enhancing its uniformity and durability.

Defoamers are used to reduce the air content in concrete and eliminate large air bubbles that are detrimental to concrete. The dosage is generally below 0.03%.

Water-retaining Agents:

When the workability of concrete cannot be completely improved with the above-mentioned raw materials, it is possible to consider using cellulose ethers, polyacrylamide, or tempering adhesives as water-retaining agents to improve the workability of concrete.

Antifreezing Agents and Early Strength Agents:

Commonly used anti-freezing agents include sodium nitrite, sodium nitrate, calcium nitrate, etc. These anti-freezing agents also have an early strength effect.

Due to regional differences, the effectiveness of various raw materials may vary. Finding the most suitable raw materials for local concrete applications requires experimentation and practical experience. Choose Fuluorui, and we'll help you solve any problems you encounter throughout the process.