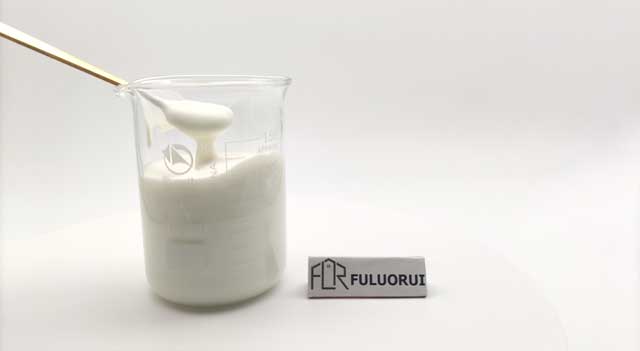

A water-based release agent for concrete is a type of agent that is soluble in water and is used to prevent concrete from sticking to formwork. It forms a smooth isolation film on the formwork, preventing direct contact between the concrete and the formwork. Its characteristics include being non-toxic, harmless, low odor, and environmentally friendly. It does not affect the strength of concrete and has no corrosive effects on steel bars. It is also easy to use and has minimal pollution.

Method of using concrete release agent:

- Before construction, clean the formwork and ensure that there is no rust, oil, or other impurities on the surface, and that the formwork is dry.

- Dilute the product with 4-6 times water (add water to the release agent) and mix well before use.

- Apply the diluted solution directly onto the formwork by brushing, rolling, or spraying. The amount used should be 10-15m/kg.

- For new formwork, pre-apply 2-3 coats of the working solution with a one-day interval between each coat.

- Apply the release agent evenly on the formwork, making sure not to miss any spots. The concrete can be poured after the film is formed (once the white color disappears).

- If construction is done outdoors, it is recommended to cover the formwork with PE film after applying the release agent. If the surface is washed by rain before the film is formed, the release agent must be reapplied.

- The diluted solution should not be used after 24 hours. If it exceeds the expiration time, it must be mixed again before use. Do not pour the diluted solution back into the original container.

Precautions for using concrete release agent:

- It is not recommended to directly pour concrete after spraying the release agent. It is better to dilute it and apply it evenly with a cloth or roller.

- If there is a long time between applying the release agent and pouring the concrete, the type of release agent should be chosen carefully. It is recommended to use an oil-based release agent with strong adhesion instead of a water-based one.

- When pouring concrete into tall and thin column molds or on sloped formwork surfaces, the release agent may be removed from the surface due to friction or low viscosity of the concrete. In this case, using multiple pouring ports and a pipeline can help reduce the harm, especially for tall and sloped formwork. Oil-based release agents are more effective in this situation than water-based ones.

- The release agent film should not be exposed to rain for a long time. If it is washed by rain, the formwork should be cleaned before reapplying the release agent.

Concrete release agents not only have good demolding effects and are easy to use, but also improve the surface and durability performance of concrete. They are cost-effective for transportation as they can be diluted with water 2-6 times and applied to formwork with a spray gun or brush.